Some Ideas on Conveyor Systems You Need To Know

Wiki Article

See This Report about Conveyor Systems

Table of ContentsNot known Factual Statements About Conveyor Systems Conveyor Systems Fundamentals ExplainedThe Basic Principles Of Conveyor Systems Not known Incorrect Statements About Conveyor Systems What Does Conveyor Systems Mean?What Does Conveyor Systems Mean?

Individuals have historically manufactured items making use of raw materials. This form of production is usually connected with decorative art, textile production, leatherwork, carpentry, and also some metalwork.Distinctive handmade style products can be marketed at a greater rate compared to something mass-produced. There are cases, though, where people who make items making use of these methods can be manipulated, specifically where labor regulations are lax as well as demand for tasks is high. Larger companies use mechanization to mass-produce things on a much larger range.

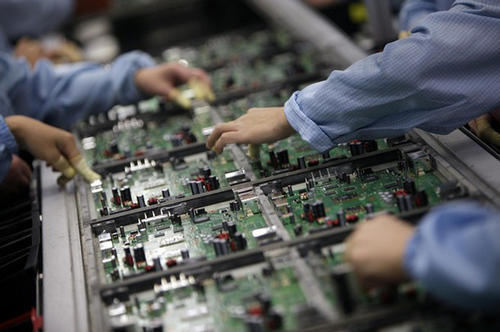

Mass manufacturing and production line production allowed companies to develop components that could be utilized interchangeably as well as allowed completed items to be conveniently made by decreasing the requirement for component modification. Ford popularized mass-production methods in the very early 20th century. Computer systems as well as accuracy electronic devices have actually since permitted business to leader sophisticated manufacturing approaches.

What Does Conveyor Systems Mean?

The volume as well as number of goods produced have increased, the number of workers called for has declined. Determining Manufacturing in the Economic Situation Financial experts as well as federal government statisticians use various ratios when examining the role production plays in the economic situation. As an example, manufacturing value included (MVA) is a sign that contrasts an economic situation's production result to its overall size.

This procedure, which converts raw materials into ended up goods, is called manufacturing. Companies can still utilize human labor to convert these materials by hand.

The Greatest Guide To Conveyor Systems

The introduction of 3D printing is making it less complicated for individuals to generate ended up products themselves, without ever leaving their very own homes.

Looking at their facilities, it's amazing how smoothly everything is working. The business representative informs us that making their own items and keeping their procedures smooth are a pair ways they keep prices reduced as well as quality high. Not all organizations resemble Make-All Sell-All, however, as well as the interpretation of hefty and light manufacturing can vary depending upon the company.

An Unbiased View of Conveyor Systems

To put it simply, what certifies as a heavy manufacturing facility in one business might qualify as a light production facility when compared to other organizations. Retail, The next area we visit is among Make-All Sell-All's retail areas. The retail center is the center that offers items to the general public.Here is visit this website additionally where customers buy these things. The firm agent claims that running their own retail centers also helps keep prices low. If you walk any kind of shopping mall, you will certainly see many retail stores. A few of these are marketing their own products. Others sell items from a number of suppliers along with their very own items, if they make them.

Service, The last location we visit is the solution center. The service facility is the center where repairs as well as various other solutions are provided. This is where consumers can send their items to get dealt with. The firm additionally has employees that make house phones call to repair large things that can not be easily delivered, like the big-screen TVs pointed out earlier.

The 6-Minute Rule for Conveyor Systems

The company rep Our site informs us that maintaining their own solution centers likewise keeps prices reduced. It is great to bear in mind that there are firms that only supply service; therefore, they just have service facilities. A carpeting shampooing business just requires a solution center that sends out the carpet shampooing vans to its consumers.In fact, a lot of services require all of these centers to operate. If the business doesn't have a particular center, then they require to collaborate with one more organization that does have that center. If a tennis footwear company does not have a repair service facility, after that they will require to function with another business that has a facility that carries out tennis shoe repair.

The production center is the facility where the business builds its items. The solution facility is the facility where repairs and also various other services are supplied.

Unknown Facts About Conveyor Systems

Discovering Outcome, As quickly as you've studied adequately, see if you can produce a listing of the various facilities an organization needs to generate, sell, as well as fix its products, as well as explain what happens in each center. To unlock this this link lesson you must be a Member. conveyor systems.Nonetheless, this very early manufacturing system altered with the introduction of the manufacturing facility system in Britain at the start of the commercial change in the late 18th century - conveyor systems. This system made the most of technological developments as well as utilized machinery powered by water, steam as well as, later on, electrical energy enabling massive manufacturing. The setting up line approach of manufacture was described by Adam Smith in The Wealth of Countries, which introduced the idea of the department of work.

Report this wiki page